Choice of Suitable PID TuningsAbstract: This paper provides an approach for the application of PID controllers

within a cascade control system configuration. Based on considerations about the

expected operating modes of both controllers, the tuning of both inner and outer loop

controllers are selected accordingly. This fact motivates the use of a tuning that,

for the secondary controller, provides a balanced set-point / load-disturbance performance.

A new approach is also provided for the assimilation of the inner closed-loop

transfer function to a suitable form for tuning of the outer controller. Due to the fact

that this inevitably introduces unmodelled dynamics into the design of the primary

controller, a robust tuning is needed.

2 Cascade Control

3 g-tuning for balanced Servo/Regulation

4 Approach for Cascade Control Design

4.1 Inner loop and outer loop process models

4.2 Inner loop controller tuning

Set-point tuning settings

Load-disturbance tuning settings

4.3 Model for Outer loop tuning

4.4 Outer loop controller tuning

5 Equivalent model approximation

6 Example

7 Conclusions

http://www.journal.univagora.ro/download/pdf/134.pdf

How to Tune Cascade Loops

1 An overview of Cascade Control.

What's The Inner Loop For?

• Reduces phase lag of inner process

• Disturbances to the inner loop are

compensated for before they upset the

outer loop

• Prevents non-linearities in the inner loop

from reaching the outer loop

2 Tuning Cascade Control Loops.

What happens when cascade loops

are poorly tuned?

• Loops “fight” each other

• Create oscillations

• Neither variable is properly controlled

• Operator puts loop in manual.

Tuning Cascade Loops

1. Always check for measurement and

valve-related issues.

2. Inner Loop Tuning - put slave into

Local Auto or Manual and tune the

slave controller as a normal PID loop.

3. Outer Loop Tuning - put slave into

Cascade and tune master controller

as a normal PID loop.

4. Adjust outer loop tuning values to

ensure that the RRT (Relative

Response Time) of outer loop is 3-5

times slower than the inner loop.

3 Case Study.

http://www.expertune.com/articles/UG2007/CascadeTuning.pdf

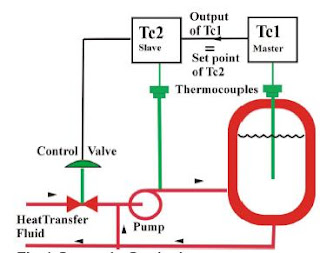

Cascade Control

Handle Processes that Challenge Regular PID Control

In previous columns we have named lags in a process as major obstacles to good temperature control. When they are inconveniently long and come in multiple stages, first try to determine where changes to process design can avoid or reduce lags. Then do your best with PID control and if you fail to obtain the response you hoped for you can turn to cascade control.

Tuning.Tune the slave loop first. Set TC1 to manual. Remove integral and derivative action from TC2 and tune it aiming for tight control. Absence of derivative avoids excessive activity of the slave loop. Overall integral action to remove offset in the vessel temperature is already provided by the master controller.

When tuning the master loop, return to cascade control, remove derivative action and tune in the normal way. Note that the slave loop now becomes part of the master loop that you are tuning at TC1. Bumpless transfer between auto, manual and cascade will be a standard feature of TC1.

Set point limits on the slave loop. If you know the range of TC2 (fluid) temperatures needed to hold the vessel temperature under all expected conditions, put those values as limits on the set point of TC2.

http://www.pacontrol.com/download/Cascade%20Control%20-%20Handle%20Processes%20that%20Challenge%20Regular%20PID%20Control.pdf

Cascade Controller - Auto Tuning

Relay Auto Tuning Of Parallel Cascade Controller

Abstract

The present work is concerned with relay auto tuning of

parallel cascade controllers. The method proposed by

Srinivasan and Chidambaram [10] to analyze the conventional

on-off relay oscillations for a single loop feedback controller is

extended to the relay tuning of parallel cascade controllers.

Using the ultimate gain and ultimate cross over frequency of

the two loops, the inner loop (PI) and outer loop (PID)

controllers are designed by Ziegler-Nichols tuning method. The

performances of the controllers are compared with the results

based on conventional relay analysis. The improved method of

analyzing biased auto tune method proposed for single

feedback controller by Srinivasan and Chidambaram [11] is

also applied to relay auto tune of parallel cascade controllers.

The proposed methods give an improved performance over that

of the conventional on-off relay tune method.

http://www.iaeng.org/publication/WCECS2007/WCECS2007_pp158-162.pdf