Video Lecture Introduction To CNC Machines

Video Lecture Contour generation and Motion Control

Video Lecture Flow Control Valves

Showing posts with label Servo Motion Control. Show all posts

Showing posts with label Servo Motion Control. Show all posts

Tuesday, December 15, 2009

Tuesday, April 28, 2009

servo motor control-Velocity Profiling

A velocity profile is a graph of the velocity of a motor vs. time. The area inside the curve that the velocity profile creates is the distance traveled. Velocity profiling is useful for applications where specific velocities are necessary at specific times. Two typical velocity profiles are shown in the following figures.

These two figures are both examples of velocity profiles that can be implemented using the FlexMotion hardware and software. In the first example, the motor simply accelerates to a target velocity at a specified acceleration, runs at the target velocity, and then decelerates after a certain amount of time. In the second example, the motor accelerates to a certain velocity, runs at that target velocity for a period of time, accelerates to a higher velocity, then travels at that velocity for a period of time, and then decelerates to zero.

National Instruments - Fundamentals of Motion Control

http://zone.ni.com/devzone/cda/tut/p/id/3367

Creation of velocity profile using s-curves

In this paper an approach is proposed for velocity profile control of an AC motor. The dynamic control algorithms for calculation and estimation of the S-curve profile adapt in real time to variations in system behavior to improve their performance.

The S-curve velocity profile is similar to trapezoidal, and in this case, trapezium sides are replaced by S-curves, which enables smoother velocity transitions in acceleration and deceleration periods [1, 9].

The first order trapezoidal velocity profile is a typical point-to-point move. An

axis accelerates from rest to a given velocity at a constant rate. Then traverses, or slews, to a certain point where it decelerates at a constant rate until finally, the end position is reached and the axis will come to a rest. Sometimes the slew velocity and the end position can be changed on the fly. The S-curve velocity profile can be represented as a second-order polynomial in velocity. We have an extra term here – jerk (jerk is a derivative of acceleration and a measure of impact). The second order S-curve provides complete flexibility in the control of profiles for smoothing motion and eliminating jerk from mechanical systems. The degree of S-curve on a motion

profile is controlled by separate acceleration and deceleration smoothing (jerk-limit) factors.

National Instruments - Fundamentals of Motion Control

http://zone.ni.com/devzone/cda/tut/p/id/3367

Creation of velocity profile using s-curves

In this paper an approach is proposed for velocity profile control of an AC motor. The dynamic control algorithms for calculation and estimation of the S-curve profile adapt in real time to variations in system behavior to improve their performance.

The S-curve velocity profile is similar to trapezoidal, and in this case, trapezium sides are replaced by S-curves, which enables smoother velocity transitions in acceleration and deceleration periods [1, 9].

The first order trapezoidal velocity profile is a typical point-to-point move. An

axis accelerates from rest to a given velocity at a constant rate. Then traverses, or slews, to a certain point where it decelerates at a constant rate until finally, the end position is reached and the axis will come to a rest. Sometimes the slew velocity and the end position can be changed on the fly. The S-curve velocity profile can be represented as a second-order polynomial in velocity. We have an extra term here – jerk (jerk is a derivative of acceleration and a measure of impact). The second order S-curve provides complete flexibility in the control of profiles for smoothing motion and eliminating jerk from mechanical systems. The degree of S-curve on a motion

profile is controlled by separate acceleration and deceleration smoothing (jerk-limit) factors.

Labels:

Motion Profiles,

Servo Motion Control

Thursday, April 23, 2009

Servo Motor Motion Profiles - S-Curve

All servo systems consist of some kind of movement of a load. The method in which the load is moved is known as the motion profile. A motion profile can be as simple as a movement from point A to point B on a single axis

The S-curve motion profile allows for a gradual change in acceleration. This helps to reduce or eliminate the problems caused from overshoot, and the result is a great deal less mechanical vibration seen by the system. The minimum acceleration points occur at the beginning and end of the acceleration period, while the maximum acceleration occurs between these two points. This gives a motion profile that is fast and accurate.

The S-curve motion profile allows for a gradual change in acceleration. This helps to reduce or eliminate the problems caused from overshoot, and the result is a great deal less mechanical vibration seen by the system. The minimum acceleration points occur at the beginning and end of the acceleration period, while the maximum acceleration occurs between these two points. This gives a motion profile that is fast and accurate.

advancedmotioncontrols

http://www.advancedmotioncontrols.com

http://www.advancedmotioncontrols.com

Labels:

Motion Profiles,

Servo Motion Control,

SERVO MOTOR

Thursday, April 2, 2009

Servo motor control - Feedforward with PIV control

Fundamentals of servo motion control

Feedforward control

That missing ingredient provided we have access to both

Velocity and acceleration commands, synched up with

position commands is feedforward control.

An example of how feedforward control may be used in

parallel with disturbance rejection control is shown

in figure 8. The key is to accurately calculate the amount

of torque required to make each move a priori. To do so,

we take the basic equation of motion

and approximate it (as follows) because the disturbance

and approximate it (as follows) because the disturbance

torque Td is unknown.

more pdf

Fundamentals of Servo Motion Control

Feedforward Control

In order to achieve near zero following or tracking error,

feedforward control is often employed. A requirement for

feedforward control is the availability of both the velocity,

and acceleration, commands synchronized with the

position commands,. An example of how feedforward

control is used in addition to disturbance rejection control is

shown in Fig. 8.

Feedforward control

That missing ingredient provided we have access to both

Velocity and acceleration commands, synched up with

position commands is feedforward control.

An example of how feedforward control may be used in

parallel with disturbance rejection control is shown

in figure 8. The key is to accurately calculate the amount

of torque required to make each move a priori. To do so,

we take the basic equation of motion

and approximate it (as follows) because the disturbance

and approximate it (as follows) because the disturbancetorque Td is unknown.

more pdf

Fundamentals of Servo Motion Control

Feedforward Control

In order to achieve near zero following or tracking error,

feedforward control is often employed. A requirement for

feedforward control is the availability of both the velocity,

and acceleration, commands synchronized with the

position commands,. An example of how feedforward

control is used in addition to disturbance rejection control is

shown in Fig. 8.

Labels:

Feedforward,

PIV,

Servo Motion Control

Wednesday, April 1, 2009

AC Servo Motor Control Algorithm

A precise control of AC servo motor using neural

network PID controller

A new control technique based on a neural network, is proposed

here for control of AC servo motors. The PID control is widely

used in servo systems as it has simple structure, safety and

reliability. However, it has certain problems in a complex system,

resulting in imperfect action in the presence of uncertain

parameters. To solve these problems, a new hybrid control

algorithm of the PID controller is proposed, which could

prove the adequacy of the proposed control algorithm through

simulation and experiments after driving the AC

servo motor system using neural network PID controller.

Structure of PID controller using neural network control

more pdf

more pdf

Position Control of an AC Servo Motor Using

VHDL & FPGA

Abstract

In this paper, a new method of controlling position of

AC Servomotor using Field Programmable Gate Array (FPGA).

FPGA controller is used to generate direction and the number of

pulses required to rotate for a given angle. Pulses are sent as a square

wave, the number of pulses determines the angle of rotation and

frequency of square wave determines the speed of rotation. The

proposed control scheme has been realized using XILINX FPGA

SPARTAN XC3S400 and tested using MUMA012PIS model

Alternating Current (AC) servomotor. Experimental results show that

the position of the AC Servo motor can be controlled effectively.

INTRODUCTION

A servo motor is an Electro-mechanical device in which the

electrical input determines the position of the armature of

a motor. The shaft of the servo motor can be positioned to a

specific angle by sending the coded signal. The AC servo

motors have been widely used in the industrial fields and

various approaches have been made to realize high

performance motion control. These can be effectively utilized

in many position control systems subjected to external

disturbances such as friction.

With successively improving reliability and performance of

digital controllers, the digital control techniques have

predominated over other analog counter parts. The advantages

of digital controllers are:

• Reconfigurability

• Power saving options

• Less external passive components

• Less sensitive to temperature variation

• High efficiency

Abstract

This paper presents a Xilinx Field Programmable Gate Array

(FPGA) based speed control of AC Servomotor using sinusoidal

PWM technique. Xilinx FPGA is a programmable logic device

developed by Xilinx which is considered as an efficient hardware

for rapid prototyping. It is used to generate 50 Hz sine wave, the

triangular wave and the sinusoidal PWM signals. The sinusoidal

pulse width controls the speed of Motor. The proposed control

scheme has been realized using Xilinx FPGA SPARTAN

XC3S400 and tested using SM115 model Alternating Current

(AC) servomotor. The result provides a controllable speed with

satisfactory dynamic and static performances.

network PID controller

A new control technique based on a neural network, is proposed

here for control of AC servo motors. The PID control is widely

used in servo systems as it has simple structure, safety and

reliability. However, it has certain problems in a complex system,

resulting in imperfect action in the presence of uncertain

parameters. To solve these problems, a new hybrid control

algorithm of the PID controller is proposed, which could

prove the adequacy of the proposed control algorithm through

simulation and experiments after driving the AC

servo motor system using neural network PID controller.

Structure of PID controller using neural network control

more pdf

more pdfPosition Control of an AC Servo Motor Using

VHDL & FPGA

Abstract

In this paper, a new method of controlling position of

AC Servomotor using Field Programmable Gate Array (FPGA).

FPGA controller is used to generate direction and the number of

pulses required to rotate for a given angle. Pulses are sent as a square

wave, the number of pulses determines the angle of rotation and

frequency of square wave determines the speed of rotation. The

proposed control scheme has been realized using XILINX FPGA

SPARTAN XC3S400 and tested using MUMA012PIS model

Alternating Current (AC) servomotor. Experimental results show that

the position of the AC Servo motor can be controlled effectively.

INTRODUCTION

A servo motor is an Electro-mechanical device in which the

electrical input determines the position of the armature of

a motor. The shaft of the servo motor can be positioned to a

specific angle by sending the coded signal. The AC servo

motors have been widely used in the industrial fields and

various approaches have been made to realize high

performance motion control. These can be effectively utilized

in many position control systems subjected to external

disturbances such as friction.

With successively improving reliability and performance of

digital controllers, the digital control techniques have

predominated over other analog counter parts. The advantages

of digital controllers are:

• Reconfigurability

• Power saving options

• Less external passive components

• Less sensitive to temperature variation

• High efficiency

more ( pdf )

New Digital Hardware Control Method for High

Performance AC Servo Motor

Abstract:

Today’s motor drives widely use Digital Signal

Processor (DSP) or Microcontroller to

implement the digital control algorithm. Most

recently new requirements have arisen. These

include faster torque control update with flexible

design capability of motion peripherals for high

performance military servo drive applications.

A Complete digital hardware based AC servo

drive development system has been developed to

satisfy increasing demand for performance

enhancement. Based on the FPGA, the system is

configurable for either induction or permanent

magnet machine servo control. The detail design

of complete hardware based high performance

AC servo drive system is discussed.

New Digital Hardware Control Method for High

Performance AC Servo Motor

Abstract:

Today’s motor drives widely use Digital Signal

Processor (DSP) or Microcontroller to

implement the digital control algorithm. Most

recently new requirements have arisen. These

include faster torque control update with flexible

design capability of motion peripherals for high

performance military servo drive applications.

A Complete digital hardware based AC servo

drive development system has been developed to

satisfy increasing demand for performance

enhancement. Based on the FPGA, the system is

configurable for either induction or permanent

magnet machine servo control. The detail design

of complete hardware based high performance

AC servo drive system is discussed.

Control Block Diagram

more pdf

FPGA Based Speed Control of AC Servomotor

Using Sinusoidal PWM

more pdf

FPGA Based Speed Control of AC Servomotor

Using Sinusoidal PWM

Abstract

This paper presents a Xilinx Field Programmable Gate Array

(FPGA) based speed control of AC Servomotor using sinusoidal

PWM technique. Xilinx FPGA is a programmable logic device

developed by Xilinx which is considered as an efficient hardware

for rapid prototyping. It is used to generate 50 Hz sine wave, the

triangular wave and the sinusoidal PWM signals. The sinusoidal

pulse width controls the speed of Motor. The proposed control

scheme has been realized using Xilinx FPGA SPARTAN

XC3S400 and tested using SM115 model Alternating Current

(AC) servomotor. The result provides a controllable speed with

satisfactory dynamic and static performances.

Labels:

Servo Motion Control,

SERVO MOTOR

Saturday, March 28, 2009

Servo Motion Control

Control

Servo Motion Control - PID Control

Servo Motion Control - PIV Control

DC Servo motor control

AC Servo Motor Control Algorithm

Servo motor control - Feedforward with PIV control

Tuning

Servo Motion Control Tuning the PID Loop

Modeling

MODELING OF A DC SERVOMOTOR

System Modeling - Linear Permanent Magnet Motors

Servo Motion Control - PID Control

Servo Motion Control - PIV Control

DC Servo motor control

AC Servo Motor Control Algorithm

Servo motor control - Feedforward with PIV control

Tuning

Servo Motion Control Tuning the PID Loop

Modeling

MODELING OF A DC SERVOMOTOR

System Modeling - Linear Permanent Magnet Motors

Labels:

Servo Motion Control,

SERVO MOTOR

Servo Motion Control Tuning the PID Loop

There are two primary ways to go about selecting the PID gains.

Either the operator uses a trial and error or an analytical approach.

Using a trial and error approach relies significantly on the

operator’s own prior experience with other servo systems. The one

significant downside to this is that there is no physical insight into

what the gains mean and there is no way to know if the gains are

optimum by any definition. However, for decades this was the

approach most commonly used. In fact, it is still used

today for low performance systems usually found in process control.

To address the need for an analytical approach, Ziegler and Nichols

[1] proposed a method based on their many years of industrial

control experience. Although they originally intended their tuning

method for use in process control, their technique can be applied to

servo control. Their procedure basically boils down to these two steps.

Step 1:

Set Ki and Kd to zero. Excite the system with a step command.

Slowly increase Kp until the shaft position begins to oscillate.

At this point, record the value of Kp and set Ko equal to this value.

Record the oscillation frequency, fo.

Step 2:

Set the final PID gains using equation (6).

Loosely speaking, the proportional term affects the overall response

Loosely speaking, the proportional term affects the overall response

Either the operator uses a trial and error or an analytical approach.

Using a trial and error approach relies significantly on the

operator’s own prior experience with other servo systems. The one

significant downside to this is that there is no physical insight into

what the gains mean and there is no way to know if the gains are

optimum by any definition. However, for decades this was the

approach most commonly used. In fact, it is still used

today for low performance systems usually found in process control.

To address the need for an analytical approach, Ziegler and Nichols

[1] proposed a method based on their many years of industrial

control experience. Although they originally intended their tuning

method for use in process control, their technique can be applied to

servo control. Their procedure basically boils down to these two steps.

Step 1:

Set Ki and Kd to zero. Excite the system with a step command.

Slowly increase Kp until the shaft position begins to oscillate.

At this point, record the value of Kp and set Ko equal to this value.

Record the oscillation frequency, fo.

Step 2:

Set the final PID gains using equation (6).

Loosely speaking, the proportional term affects the overall response

Loosely speaking, the proportional term affects the overall responseof the system to a position error. The integral term is needed to force

the steady state position error to zero for a constant position

command and the derivative term is needed to provide a damping

action, as the response becomes oscillatory. Unfortunately all three

parameters are inter-related so that by adjusting one parameter will

effect any of a previous parameter adjustments. As an example of

this tuning approach, we investigate the response of a Compumotor

BE342A motor with a generic servo drive and controller.

This servomotor has the following parameters:

Motor Total Inertia J = 50E-6 kgm^2

Motor Damping b = .1E-3 Nm/ (rad/sec)

Torque Constant Kt = .6 Nm/A

We begin with observing the response to a step input command with

no disturbance torque (Td = 0).

Step 1:

Fig. 2a shows the result of slowly increasing only the proportional term.

The system begins to oscillate at approximately .5 Hz (fo = .5Hz) with

Ko of approximately 5E-5 Nm/ rad.

Step 2:

the steady state position error to zero for a constant position

command and the derivative term is needed to provide a damping

action, as the response becomes oscillatory. Unfortunately all three

parameters are inter-related so that by adjusting one parameter will

effect any of a previous parameter adjustments. As an example of

this tuning approach, we investigate the response of a Compumotor

BE342A motor with a generic servo drive and controller.

This servomotor has the following parameters:

Motor Total Inertia J = 50E-6 kgm^2

Motor Damping b = .1E-3 Nm/ (rad/sec)

Torque Constant Kt = .6 Nm/A

We begin with observing the response to a step input command with

no disturbance torque (Td = 0).

Step 1:

Fig. 2a shows the result of slowly increasing only the proportional term.

The system begins to oscillate at approximately .5 Hz (fo = .5Hz) with

Ko of approximately 5E-5 Nm/ rad.

Step 2:

Using these values, the optimum P.I .D. gains according to

Ziegler-Nichols (Z-N) are then (using equation (6)):

Kp = 3.0E-4 Nm/ rad

Ki = 3.0E-4 Nm/ (rad/sec)

Kd = 7.4E-5 Nm/ (rad/sec)

Fig. 2b shows the result of using the Ziegler Nichols gains.

The response is somewhat better than just a straight proportional gain.

As a comparison, other gains were obtained by trial and error. One set

Of additional gains is listed in Fig. 2b. Although the trial and error gains

gave a faster, less oscillatory response, there is no way of telling if a

better solution exits without further exhaustive testing.

Ziegler-Nichols (Z-N) are then (using equation (6)):

Kp = 3.0E-4 Nm/ rad

Ki = 3.0E-4 Nm/ (rad/sec)

Kd = 7.4E-5 Nm/ (rad/sec)

Fig. 2b shows the result of using the Ziegler Nichols gains.

The response is somewhat better than just a straight proportional gain.

As a comparison, other gains were obtained by trial and error. One set

Of additional gains is listed in Fig. 2b. Although the trial and error gains

gave a faster, less oscillatory response, there is no way of telling if a

better solution exits without further exhaustive testing.

One characteristic that is very apparent in Fig.2 is the length of

the settling time. The system using Ziegler Nichols takes about

6 seconds to finally settle making it very difficult to incorporate

into any highperformance motion control application. In contrast,

the trial and error settings gives a quicker settling time, however

no solution was found to completely remove the overshoot.

Source ( pdf )

http://www.compumotor.com/whitepages/ServoFundamentals.pdf

the settling time. The system using Ziegler Nichols takes about

6 seconds to finally settle making it very difficult to incorporate

into any highperformance motion control application. In contrast,

the trial and error settings gives a quicker settling time, however

no solution was found to completely remove the overshoot.

Source ( pdf )

http://www.compumotor.com/whitepages/ServoFundamentals.pdf

Labels:

PID,

Servo Motion Control,

SERVO MOTOR,

Tuning

Friday, March 27, 2009

DC Servo motor control

NEURAL ADAPTIVE TACKING CONTROL OF A

LOW SPEED DC SERVO SYSTEM

Hu Hongjie Chen Jingquan Er Lianjie

DC SERVO SYSTEM

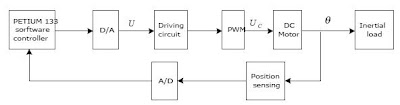

The low speed system’s hardware setup is composed of a

permanent dc motor, driving circuit, servo amplifier

(PWM), a mechanical frame as an inertial load, interface

circuit (A/D and D/A), an encoder for position sensing,

and a personal computer (PETIUM I 133) is used as the

programming environment, using Borlandc31 as

programming language for the real-time control

application. Sampling time is defined as 5ms. The block

diagram of the hardware setup is shown in figure

more ( pdf )

Two Adaptive Friction Compensation for DC Servomotors

Abstract

Two advanced control strategies of adaptive friction

Compensation For DC servomotor are presented in this paper,

the first is used for The direct on-line friction compensation in

the velocity control system, The second is making use of an

adaptive inverse neural network controller In the position control

system. Both are composed of an adaptive Compensator for

the nonlinear stiction and Coulomp friction in Parallel with a

PID regulator. Experiments show that much improvement

Of performance has attained respect to conventional controller

Two Adaptive Friction Compensation for DC Servomotors

Abstract

Two advanced control strategies of adaptive friction

Compensation For DC servomotor are presented in this paper,

the first is used for The direct on-line friction compensation in

the velocity control system, The second is making use of an

adaptive inverse neural network controller In the position control

system. Both are composed of an adaptive Compensator for

the nonlinear stiction and Coulomp friction in Parallel with a

PID regulator. Experiments show that much improvement

Of performance has attained respect to conventional controller

more ( pdf )

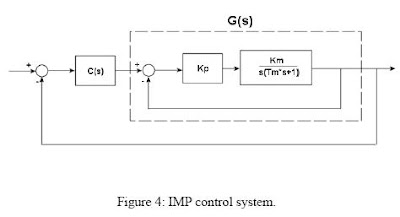

Feedforward and IMP Control Applied to a DC Servo Motor

Feedforward and IMP Control Applied to a DC Servo Motor

1.0 Introduction

The purpose of this report is to compare feedforward and internal

model principle (IMP) control applied to a DC servo motor.

These control schemes will be tested with known sinusoidal inputs.

The performance of the control schemes will be compared to the

Open loop performance of the system. System identification of

the motor is another task that will be performed.

Feedforward Control

Feedforward control was implemented by inverting (2) to yield:

this gives an overall transfer function of one for the system as

can be seen from figure 3. Even though H(s) is not a proper

transfer function, the control system could be implemented

because the input signal is a known sine wave so the first and

second derivatives can be readily calculated.

can be seen from figure 3. Even though H(s) is not a proper

transfer function, the control system could be implemented

because the input signal is a known sine wave so the first and

second derivatives can be readily calculated.

Internal Model Principle Control (IMP)

The internal model principle [Control System Design, Goodwin

et. al.] can be used to design a controller when the input to the

system is know and can be modeled in the Laplace domain.

The internal model principle [Control System Design, Goodwin

et. al.] can be used to design a controller when the input to the

system is know and can be modeled in the Laplace domain.

more ( pdf )

MODELLING AND CONTROL OF A DC SERVO MOTOR

WITH LABVIEW

MODELLING AND CONTROL OF A DC SERVO MOTOR

WITH LABVIEW

OBJECTIVES

This is a hands-on session on the application of computer-based

control to a voltage-controllable electro-mechanical system – the

DC motor. The session is mainly concerned with the modelling

and control of a DC servo motor system, fully instrumented with

position and velocity measurements. National Instrument’s

LabVIEW will be the control software for the experiment. At the

end of the experiment, you should have some experience in

• Simple static and dynamic modelling of the DC motor system,

• Manual and feedback control of the system for velocity tracking

To benefit more fully from this session, students should read the

manual and answer the pre-laboratory questions (Q1-Q3) before

going to the laboratory.

Fig1. DC Servomotor

More pdf

Real –Time DC Motor Position Control by Fuzzy Logic

and PID Controllers Using Labview

Abstract

This paper presents the position control of a DC

motor using Fuzzy Logic and PID Control algorithms. Fuzzy

Logic and PID controllers are designed based on labview

program, and the real - time position control of the DC motor

was realized by using DAQ device. The experimental results

demonstrate that the responses of DC motor with FLC show a

satisfactory, well damped control performance.

Fig .3. The block diagram of proposed PID Controller structure

More pdf

DC Servomotor Controller

This is an experiment on the closed loop DC servomotor control

system (SMC). It will able to be used for practical use with/without

some modifications. The closed loop servo mechanism requires

real-time servo operations, such as position control, velocity

control and torque control. It will be suitable for implementation

to any embedded 32 bit RISC processors as a middleware. In this

project, these operations are processed with only a cheap 8 bit

microcontroller.

Labels:

Servo Motion Control,

SERVO MOTOR

Friday, March 20, 2009

Servo Motion - Control PIV Control

In order to be able to better predict the system response, an

alternative topology is needed. One example of an easier to

tune topology is the PIV controller shown in Fig.3. This

controller basically combines a position loop with a velocity loop.

More specifically, the result of the position error multiplied

by Kp becomes a velocity correction command. The integral

term, Ki now operates directly on the velocity error instead of

the position error as in the PID case and finally, the Kd term

in the PID position loop is replaced by a Kv term in the PIV

velocity loop. Note however, they have the same units,

Nm/ (rad/sec).

alternative topology is needed. One example of an easier to

tune topology is the PIV controller shown in Fig.3. This

controller basically combines a position loop with a velocity loop.

More specifically, the result of the position error multiplied

by Kp becomes a velocity correction command. The integral

term, Ki now operates directly on the velocity error instead of

the position error as in the PID case and finally, the Kd term

in the PID position loop is replaced by a Kv term in the PIV

velocity loop. Note however, they have the same units,

Nm/ (rad/sec).

PIV control requires the knowledge of the motor velocity,

labeled velocity estimator in Fig.3. This is usually formed by

a simple filter, however significant delays can result and must

be accounted for if truly accurate responses are needed.

Alternatively, the velocity can be obtained by use of a velocity

observer. This observer requires the use of other state variables

in exchange for providing zero lag filtering properties. In either

case, a clean velocity signal must be provided for PIV control.

As an example of this tuning approach, we investigate the

response of a Compumotor Gemini series servo drive and built in

controller using the same motor from the previous example.

Again, we begin with observing the response to a step input

command with no external disturbance torque (Td = 0).

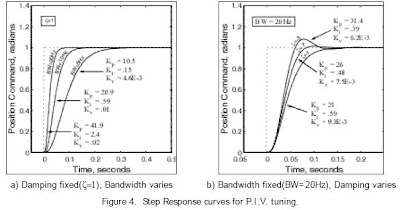

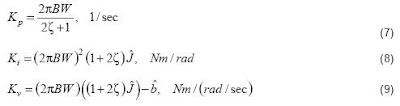

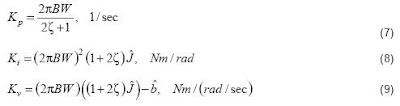

Tuning the PIV Loop

To tune this system, only two control parameters are needed,

the bandwidth (BW) and the damping ratio (z). An estimate

of the motor’s total inertia, ˆ J and damping, ˆ b are also required

at set-up and are obtained using the motor/drive set up utilities.

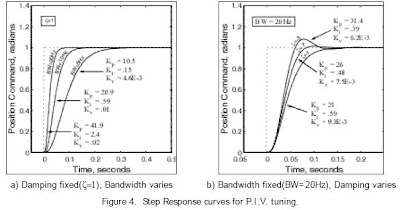

Figure 4 illustrates typical response plots for various bandwidths

and damping ratios.

labeled velocity estimator in Fig.3. This is usually formed by

a simple filter, however significant delays can result and must

be accounted for if truly accurate responses are needed.

Alternatively, the velocity can be obtained by use of a velocity

observer. This observer requires the use of other state variables

in exchange for providing zero lag filtering properties. In either

case, a clean velocity signal must be provided for PIV control.

As an example of this tuning approach, we investigate the

response of a Compumotor Gemini series servo drive and built in

controller using the same motor from the previous example.

Again, we begin with observing the response to a step input

command with no external disturbance torque (Td = 0).

Tuning the PIV Loop

To tune this system, only two control parameters are needed,

the bandwidth (BW) and the damping ratio (z). An estimate

of the motor’s total inertia, ˆ J and damping, ˆ b are also required

at set-up and are obtained using the motor/drive set up utilities.

Figure 4 illustrates typical response plots for various bandwidths

and damping ratios.

With the damping ratio fixed, the bandwidth directly relates to

the system rise time as shown in Fig.4 a). The higher the bandwidth,

the quicker the rise and settling times. Damping, on the other hand,

relates primary to overshoot and secondarily to rise time. The less

damping, the higher the overshoot and the slightly quicker the rise

time for a fixed bandwidth. This scenario is shown in Fig. 4 b).

The actual internal PIV gains can be calculated directly from

the bandwidth and damping values along with the estimates of

the inertia, ˆ J and motor viscous damping, ˆ b , making their use

straightforward and easy to implement. The actual analytical

expressions are described in equations (7) - (9).

the system rise time as shown in Fig.4 a). The higher the bandwidth,

the quicker the rise and settling times. Damping, on the other hand,

relates primary to overshoot and secondarily to rise time. The less

damping, the higher the overshoot and the slightly quicker the rise

time for a fixed bandwidth. This scenario is shown in Fig. 4 b).

The actual internal PIV gains can be calculated directly from

the bandwidth and damping values along with the estimates of

the inertia, ˆ J and motor viscous damping, ˆ b , making their use

straightforward and easy to implement. The actual analytical

expressions are described in equations (7) - (9).

In reality, the user never wants to put a step command into their

mechanics, unless of course the step is so small that no damage

will result. The use of a step response in determining a system’s

performance is mostly traditional. The structure of the PIV

control and for that matter, the PID control is designed to reject

unknown disturbances to the system. Fig.1 shows this unknown

torque disturbance, Td as part of the servo motor model.

Source ( pdf )

http://www.compumotor.com/whitepages/ServoFundamentals.pdf

mechanics, unless of course the step is so small that no damage

will result. The use of a step response in determining a system’s

performance is mostly traditional. The structure of the PIV

control and for that matter, the PID control is designed to reject

unknown disturbances to the system. Fig.1 shows this unknown

torque disturbance, Td as part of the servo motor model.

Source ( pdf )

http://www.compumotor.com/whitepages/ServoFundamentals.pdf

Labels:

PIV,

Servo Motion Control,

Tuning

Thursday, March 19, 2009

Servo Motion Control - PID Control

PID position loops

Theory

The velocity loop is the most basic servo control loop. However,

since a velocity loop cannot ensure that the machine stays in

position over long periods of time, most applications require

position control. There are two common configurations used for

position control: the cascaded position-velocity loop, as discussed

last month, and the PID position controller, as shown below.

Block diagram of PID position loop

The position loop compares a position command to a position

feedback signal, and calculates the position error, PE. In a PID

controller, current command is generated with three gains: PE is

scaled by the proportional gain (KPP), the integral of PE is scaled by

the integral gain (KPI), and the derivative of PE is scaled by the

derivative gain (KPD).

More ( pdf )

http://apps.danahermotion.com/support/troubleshooting/

PDF_Resources/2000-08%20PID%20pos%20loops.pdf

Servo Motion Control - PID Control

Theory

The velocity loop is the most basic servo control loop. However,

since a velocity loop cannot ensure that the machine stays in

position over long periods of time, most applications require

position control. There are two common configurations used for

position control: the cascaded position-velocity loop, as discussed

last month, and the PID position controller, as shown below.

Block diagram of PID position loop

The position loop compares a position command to a position

feedback signal, and calculates the position error, PE. In a PID

controller, current command is generated with three gains: PE is

scaled by the proportional gain (KPP), the integral of PE is scaled by

the integral gain (KPI), and the derivative of PE is scaled by the

derivative gain (KPD).

More ( pdf )

http://apps.danahermotion.com/support/troubleshooting/

PDF_Resources/2000-08%20PID%20pos%20loops.pdf

Servo Motion Control - PID Control

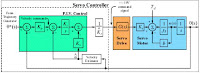

The basic components of a typical servo motion system are

depicted in Fig.1 using standard LaPlace notation. In this figure,

the servo drive closes a current loop and is modeled simply as

a linear transfer function G(s). Of course the servo drive will

have peak current limits, so this linear model is not entirely

accurate, however it does provide a reasonable representation

for our analysis. In their most basic form, servo drives receive

a voltage command that represents a desired motor current.

Motor shaft torque, T is related to motor current, I by the torque

constant, Kt. Equation (1) shows this relationship.

For the purposes of this discussion the transfer function of

For the purposes of this discussion the transfer function of

the current regulator or really the torque regulator can be

approximated as unity for the relatively lower motion frequencies

we are interested in and therefore we make the following

approximation shown in (2).

The servomotor is modeled as a lump inertia, J, a viscous damping

The servomotor is modeled as a lump inertia, J, a viscous damping

term, b, and a torque constant, Kt. The lump inertia term is

comprised of both the servomotor and load inertia. I t is also

assumed that the load is rigidly coupled such that the torsional

rigidity moves the natural mechanical resonance point well

out beyond the servo controller’s bandwidth. This assumption

allows us to model the total system inertia as the sum of the

motor and load inertia for the frequencies we can control.

Somewhat more complicated models are needed if coupler

dynamics are incorporated.

The actual motor position, q(s) is usually measured by either an

encoder or resolver coupled directly to the motor shaft. Again the

underlying assumption is that the feedback device is rigidly

mounted such that its mechanical resonant frequencies can be

safely ignored. External shaft torque disturbances, Td are added

to the torque generated by the motor's current to give the torque

available to accelerate the total inertia, J.

There are three gains to adjust in the PID controller, Kp, Ki and Kd.

There are three gains to adjust in the PID controller, Kp, Ki and Kd.

These gains all act on the position error defined in (4). Note the

superscript "* " refers to a commanded value.

depicted in Fig.1 using standard LaPlace notation. In this figure,

the servo drive closes a current loop and is modeled simply as

a linear transfer function G(s). Of course the servo drive will

have peak current limits, so this linear model is not entirely

accurate, however it does provide a reasonable representation

for our analysis. In their most basic form, servo drives receive

a voltage command that represents a desired motor current.

Motor shaft torque, T is related to motor current, I by the torque

constant, Kt. Equation (1) shows this relationship.

For the purposes of this discussion the transfer function of

For the purposes of this discussion the transfer function ofthe current regulator or really the torque regulator can be

approximated as unity for the relatively lower motion frequencies

we are interested in and therefore we make the following

approximation shown in (2).

The servomotor is modeled as a lump inertia, J, a viscous damping

The servomotor is modeled as a lump inertia, J, a viscous dampingterm, b, and a torque constant, Kt. The lump inertia term is

comprised of both the servomotor and load inertia. I t is also

assumed that the load is rigidly coupled such that the torsional

rigidity moves the natural mechanical resonance point well

out beyond the servo controller’s bandwidth. This assumption

allows us to model the total system inertia as the sum of the

motor and load inertia for the frequencies we can control.

Somewhat more complicated models are needed if coupler

dynamics are incorporated.

The actual motor position, q(s) is usually measured by either an

encoder or resolver coupled directly to the motor shaft. Again the

underlying assumption is that the feedback device is rigidly

mounted such that its mechanical resonant frequencies can be

safely ignored. External shaft torque disturbances, Td are added

to the torque generated by the motor's current to give the torque

available to accelerate the total inertia, J.

Around the servo drive and motor block is the servo controller that

closes the position loop. A basic servo controller generally contains

both a trajectory generator and a PID controller. The trajectory

generator typically provides only position setpoint commands labeled

in Fig.1 as q* (s). The PID controller operates on the position error

and outputs a torque command that is sometimes scaled by an

estimate of the motor's torque constant, ˆt K . I f the motor's torque

constant is not known, the PID gains are simply re-scaled accordingly.

Because the exact value of the motor's torque constant is generally

not known, the symbol "^ " is used to indicate it is an estimated value

in the controller. In general, equation (3) holds with sufficient accuracy

so that the output of the servo controller (usually + / - 10 volts) will

command the correct amount of current for a desired torque.

closes the position loop. A basic servo controller generally contains

both a trajectory generator and a PID controller. The trajectory

generator typically provides only position setpoint commands labeled

in Fig.1 as q* (s). The PID controller operates on the position error

and outputs a torque command that is sometimes scaled by an

estimate of the motor's torque constant, ˆt K . I f the motor's torque

constant is not known, the PID gains are simply re-scaled accordingly.

Because the exact value of the motor's torque constant is generally

not known, the symbol "^ " is used to indicate it is an estimated value

in the controller. In general, equation (3) holds with sufficient accuracy

so that the output of the servo controller (usually + / - 10 volts) will

command the correct amount of current for a desired torque.

There are three gains to adjust in the PID controller, Kp, Ki and Kd.

There are three gains to adjust in the PID controller, Kp, Ki and Kd.These gains all act on the position error defined in (4). Note the

superscript "* " refers to a commanded value.

Labels:

PID,

Servo Motion Control

Subscribe to:

Posts (Atom)