NEURAL ADAPTIVE TACKING CONTROL OF A

LOW SPEED DC SERVO SYSTEM

Hu Hongjie Chen Jingquan Er Lianjie

DC SERVO SYSTEM

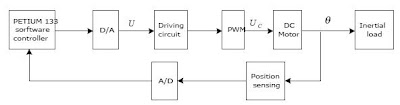

The low speed system’s hardware setup is composed of a

permanent dc motor, driving circuit, servo amplifier

(PWM), a mechanical frame as an inertial load, interface

circuit (A/D and D/A), an encoder for position sensing,

and a personal computer (PETIUM I 133) is used as the

programming environment, using Borlandc31 as

programming language for the real-time control

application. Sampling time is defined as 5ms. The block

diagram of the hardware setup is shown in figure

more ( pdf )

Two Adaptive Friction Compensation for DC Servomotors

Abstract

Two advanced control strategies of adaptive friction

Compensation For DC servomotor are presented in this paper,

the first is used for The direct on-line friction compensation in

the velocity control system, The second is making use of an

adaptive inverse neural network controller In the position control

system. Both are composed of an adaptive Compensator for

the nonlinear stiction and Coulomp friction in Parallel with a

PID regulator. Experiments show that much improvement

Of performance has attained respect to conventional controller

Two Adaptive Friction Compensation for DC Servomotors

Abstract

Two advanced control strategies of adaptive friction

Compensation For DC servomotor are presented in this paper,

the first is used for The direct on-line friction compensation in

the velocity control system, The second is making use of an

adaptive inverse neural network controller In the position control

system. Both are composed of an adaptive Compensator for

the nonlinear stiction and Coulomp friction in Parallel with a

PID regulator. Experiments show that much improvement

Of performance has attained respect to conventional controller

more ( pdf )

Feedforward and IMP Control Applied to a DC Servo Motor

Feedforward and IMP Control Applied to a DC Servo Motor

1.0 Introduction

The purpose of this report is to compare feedforward and internal

model principle (IMP) control applied to a DC servo motor.

These control schemes will be tested with known sinusoidal inputs.

The performance of the control schemes will be compared to the

Open loop performance of the system. System identification of

the motor is another task that will be performed.

Feedforward Control

Feedforward control was implemented by inverting (2) to yield:

this gives an overall transfer function of one for the system as

can be seen from figure 3. Even though H(s) is not a proper

transfer function, the control system could be implemented

because the input signal is a known sine wave so the first and

second derivatives can be readily calculated.

can be seen from figure 3. Even though H(s) is not a proper

transfer function, the control system could be implemented

because the input signal is a known sine wave so the first and

second derivatives can be readily calculated.

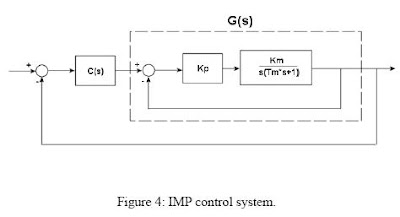

Internal Model Principle Control (IMP)

The internal model principle [Control System Design, Goodwin

et. al.] can be used to design a controller when the input to the

system is know and can be modeled in the Laplace domain.

The internal model principle [Control System Design, Goodwin

et. al.] can be used to design a controller when the input to the

system is know and can be modeled in the Laplace domain.

more ( pdf )

MODELLING AND CONTROL OF A DC SERVO MOTOR

WITH LABVIEW

MODELLING AND CONTROL OF A DC SERVO MOTOR

WITH LABVIEW

OBJECTIVES

This is a hands-on session on the application of computer-based

control to a voltage-controllable electro-mechanical system – the

DC motor. The session is mainly concerned with the modelling

and control of a DC servo motor system, fully instrumented with

position and velocity measurements. National Instrument’s

LabVIEW will be the control software for the experiment. At the

end of the experiment, you should have some experience in

• Simple static and dynamic modelling of the DC motor system,

• Manual and feedback control of the system for velocity tracking

To benefit more fully from this session, students should read the

manual and answer the pre-laboratory questions (Q1-Q3) before

going to the laboratory.

Fig1. DC Servomotor

More pdf

Real –Time DC Motor Position Control by Fuzzy Logic

and PID Controllers Using Labview

Abstract

This paper presents the position control of a DC

motor using Fuzzy Logic and PID Control algorithms. Fuzzy

Logic and PID controllers are designed based on labview

program, and the real - time position control of the DC motor

was realized by using DAQ device. The experimental results

demonstrate that the responses of DC motor with FLC show a

satisfactory, well damped control performance.

Fig .3. The block diagram of proposed PID Controller structure

More pdf

DC Servomotor Controller

This is an experiment on the closed loop DC servomotor control

system (SMC). It will able to be used for practical use with/without

some modifications. The closed loop servo mechanism requires

real-time servo operations, such as position control, velocity

control and torque control. It will be suitable for implementation

to any embedded 32 bit RISC processors as a middleware. In this

project, these operations are processed with only a cheap 8 bit

microcontroller.